© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

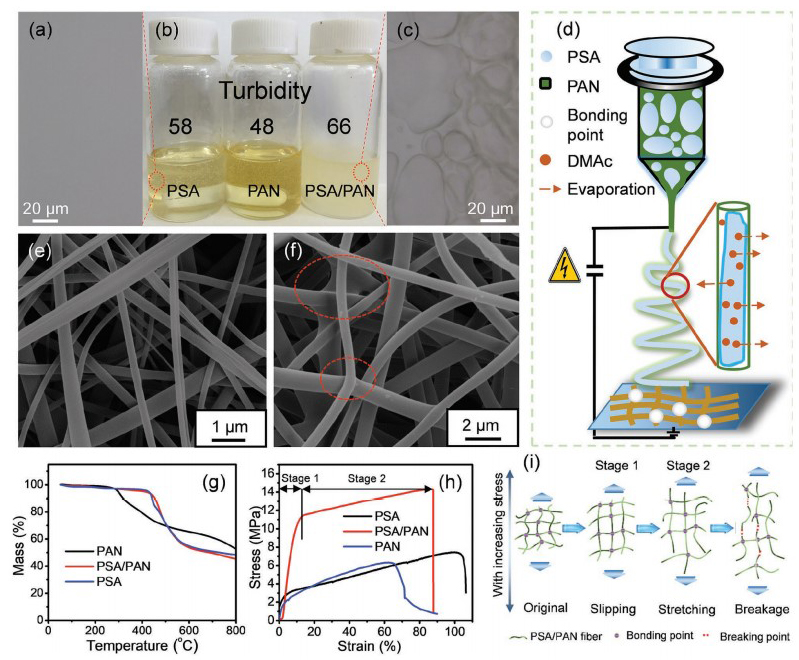

Fouling of polymeric membranes remains a major challenge for long-term operation of oily-water remediation. The common reclamation methods to recycle fouled membranes have the issues of either incomplete degradation of organic pollutants or damage to filter membranes. Here, a calcinable polymer membrane with effective reclamation after fouling is reported, which shows full recovery of the original oil/water separation efficiency. The membrane is made of polysulfonamide/polyacrylonitrile fibers by emulsion electrospinning, followed by hydrothermal decoration of TiO2 nanoparticles. The bonding structured fibrous membrane displays outstanding thermal stability in air (400 degrees C), strong acid/alkali resistance (at the pH range from 1 to 13), and robust tensile strength. As a result, the chemically fouled polymeric membrane can be easily reclaimed without decreasing in separation performance and mechanical properties by annealing treatment. As a proof-of-concept, the as-prepared membrane is integrated into a wastewater separation tank, which achieves a high water flux over 3000 L m(-2) h(-1) and oil rejection efficiency of 99.6% for various oil-in-water emulsions. The presented strategy on membrane fabrication is believed to be an effective remedy for membrane fouling, and should apply in a wider field of filtration industry.

聚合物膜的结垢仍然是油水修复的长期运行的主要挑战。回收污垢膜的常用回收方法存在有机污染物降解不完全或滤膜损坏的问题。在这里,报道了在结垢后具有有效回收的可煅烧聚合物膜,该膜显示了完全的原始油/水分离效率的恢复。该膜由聚磺酰胺/聚丙烯腈纤维通过乳液静电纺丝制成,然后对TiO2纳米粒子进行水热装饰。粘结结构的纤维膜在空气中(400摄氏度)显示出出色的热稳定性,强的耐酸/碱性(在1至13的pH范围内)和强大的拉伸强度。结果,可以容易地回收化学结垢的聚合物膜,而不会由于退火处理而降低分离性能和机械性能。作为概念验证,将制得的膜集成到废水分离罐中,该分离罐可在3000 L m(-2)h(-1)内实现高水通量,对各种机油的排油效率为99.6%。所提出的关于膜制造的策略被认为是对膜结垢的有效补救方法,并且应在更广泛的过滤工业领域中应用。

Published:2018

Journal :ADVANCED MATERIALS

Impact Factor:27.002

Paper link: https://onlinelibrary.wiley.com/doi/abs/10.1002/adma.201801870