© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

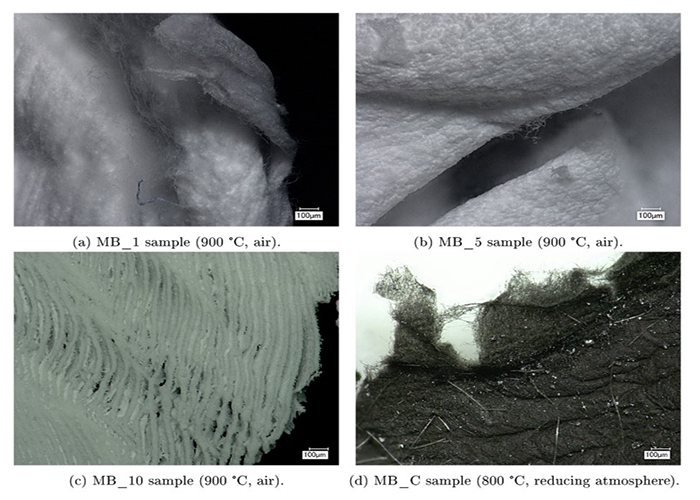

The influence of different heating rates as well as different atmospheres on magnesium borate fibers produced by electrospinning was investigated in this work. The green fibers were prepared from sol gel precursors, using polyvinyl-pyrrolidone (PVP) as processing aid. Crystalline fibers with the typical necklace structure and average diameter in the range 300-500 nm were produced when heating up to 900 degrees C in air. The main phase detected by XRD analysis was in this case Mg2B2O5. On the other hand, the fibers slowly heated in reducing atmosphere to 800 degrees C exhibited similar dimension but a different morphology. The crystalline grains were presumably smaller, hence the necklace effect was absent. This sample also revealed a much higher specific surface area in comparison to the samples calcined in air. Mg3B2O6 was here the main crystalline phase, while a part of boron was lost during the thermal treatment.

在这项工作中,研究了不同的加热速率以及不同的气氛对静电纺丝生产的硼酸镁纤维的影响。 使用聚乙烯吡咯烷酮(PVP)作为加工助剂,由溶胶凝胶前体制备生纤维。 当在空气中加热到900摄氏度时,会生产出具有典型项链结构且平均直径在300-500 nm范围内的结晶纤维。 通过XRD分析检测到的主要相在这种情况下是Mg 2 B 2 O 5。 另一方面,在还原性气氛中缓慢加热至800℃的纤维表现出相似的尺寸但形态不同。 晶粒可能较小,因此没有项链效应。 与在空气中煅烧的样品相比,该样品还显示出高得多的比表面积。 Mg3B2O6在这里是主要的结晶相,而一部分硼在热处理过程中损失了。

Published: 2018

Journal :JOURNAL OF THE EUROPEAN CERAMIC SOCIETY

Impact Factor:4.799

Paper link: https://www.sciencedirect.com/science/article/abs/pii/S0955221918302632