© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

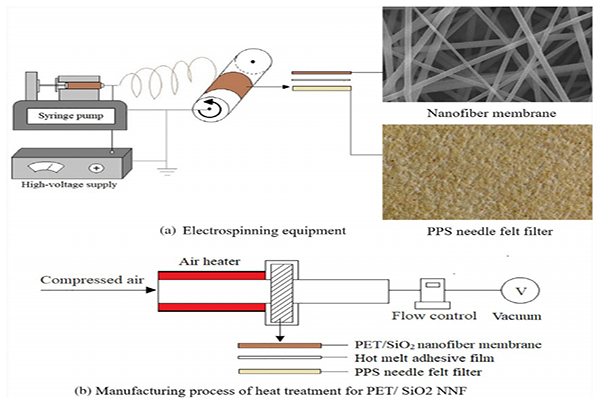

In this study, polyethylene terephthalate (PET) nanofiber membrane fabricated by electrospinning was newly applied to needle-felt filters. The PET nanofiber membrane was electrospun in an optimal condition. Nanoparticles (SiO2) were used to reduce the fiber diameter. Polyphenylene sulfide needle felt (PPS NF), hot melt adhesive film, and PET nanofiber membrane were compounded into sandwich-structured composite needle felt (PET/SiO2 NNF) by heat treatment. The dynamic filtration performance of PET/SiO2 NNF was compared with that of PPS NF and polytetrafluoroethylene-coated needle felt (PTFE CNF). The results showed that PET/SiO2 NNF had a lower rate of increase of pressure drop and a higher dust removal rate. The completion cycle of PET/SiO2 NNF was longer than PPS NF and PTFE CNF, which extended its service life in real applications. The successful synthesis of PET/SiO2 NNF suggested a new method to synthesize an innovative high-performance needle-felt filter. (c) 2019 Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2019, 136, 48282.

在这项研究中,通过静电纺丝制造的聚对苯二甲酸乙二酯(PET)纳米纤维膜被新应用于针刺毡过滤器。在最佳条件下对PET纳米纤维膜进行电纺。纳米颗粒(SiO2)用于减小纤维直径。通过热处理将聚苯硫醚针刺毡(PPS NF),热熔胶膜和PET纳米纤维膜复合成夹心结构的复合针刺毡(PET / SiO2 NNF)。将PET / SiO2 NNF的动态过滤性能与PPS NF和聚四氟乙烯涂层的针刺毡(PTFE CNF)的动态过滤性能进行了比较。结果表明,PET / SiO2 NNF的压降增加率较低,除尘率较高。 PET / SiO2 NNF的完成周期比PPS NF和PTFE CNF长,从而延长了其在实际应用中的使用寿命。 PET / SiO2 NNF的成功合成为合成创新的高性能针毡过滤器提供了一种新方法。 (c)2019年Wiley Periodicals,Inc.J.Appl。 Polym。科学2019,136,48282。

Published: 2020

Journal :JOURNAL OF APPLIED POLYMER SCIENCE

Impact Factor:2.668

Paper link: https://onlinelibrary.wiley.com/doi/abs/10.1002/app.48282