© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

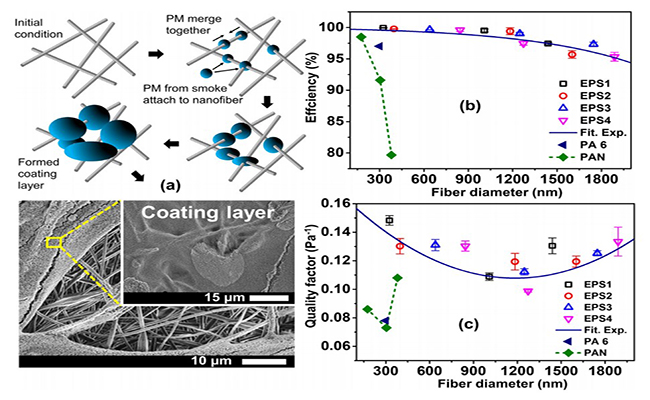

This paper reported on the fabrication of nanofibrous membranes from various sources of expanded polystyrene (EPS) waste using electrospinning technique and their application as air filter media. The filter membranes were made from four EPS waste sources, i.e. food packaging, EPS craft, instant noodle cup, and electronic packaging. The properties of the membranes fabricated from those sources were compared to obtain the best EPS waste source for air filter application. To make the precursor solutions, those samples were dissolved in d-limonene:DMF with the concentration of 15, 20, and 25 wt%. The solid EPS density, solution viscosity, and surface tension were measured. The fiber diameter and morphology of nanofibers were characterized by scanning electron microscopy (SEM) for each EPS variation. The fabricated membrane properties (crystallinity, wettability, and mechanical strength) and filtration properties (pressure drop, PM2.5 filtration efficiency, and quality factor) were fully characterized and analyzed. Homogeneous fiber diameter with various morphologies (beaded, wrinkled, and smooth fiber) were obtained from all samples with hydrophobic to super-hydrophobic surface (water contact angle ranging from 106 to 153 degrees). Also, the EPS solid density affected the solution viscosity with the expression of eta = 0.132 rho(0.29), which then affected the fabricated membrane packing density, porosity, and mechanical properties. Overall, the experimental results showed that all EPS nanofiber filters had great potential as an air filter media. The EPS filter made from food packaging waste with the solution concentration of 15 wt% exhibited the highest efficiency and quality factor of 99.99% and 0.15 Pa-1, respectively.

本文报道了使用静电纺丝技术从各种来源的膨胀聚苯乙烯(EPS)废料制备纳米纤维膜及其在空气过滤介质中的应用。滤膜由四种EPS废物源制成,即食品包装,EPS工艺,方便面杯和电子包装。比较了由这些来源制成的膜的性能,以获得用于空气过滤器应用的最佳EPS废物来源。为了制备前体溶液,将这些样品溶解在浓度为15、20和25 wt%的d-柠檬烯:DMF中。测量了固体EPS密度,溶液粘度和表面张力。纳米纤维的纤维直径和形态通过扫描电子显微镜(SEM)对每个EPS变化进行表征。充分表征和分析了所制造的膜性能(结晶度,润湿性和机械强度)和过滤性能(压降,PM2.5过滤效率和品质因数)。从具有疏水性至超疏水性表面(水接触角范围为106至153度)的所有样品中获得具有各种形态(珠状,皱纹和光滑纤维)的均质纤维直径。同样,EPS固体密度以eta = 0.132 rho(0.29)的形式影响溶液的粘度,然后影响所制造的膜的堆积密度,孔隙率和机械性能。总体而言,实验结果表明,所有EPS纳米纤维过滤器都具有作为空气过滤介质的巨大潜力。由食品包装废料制成的EPS过滤器的溶液浓度为15 wt%,其最高效率和品质因数分别为99.99%和0.15 Pa-1。

Published: 2020

Journal :WASTE MANAGEMENT

Impact Factor:6.227

Paper link: https://www.sciencedirect.com/science/article/abs/pii/S0956053X19307585