© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

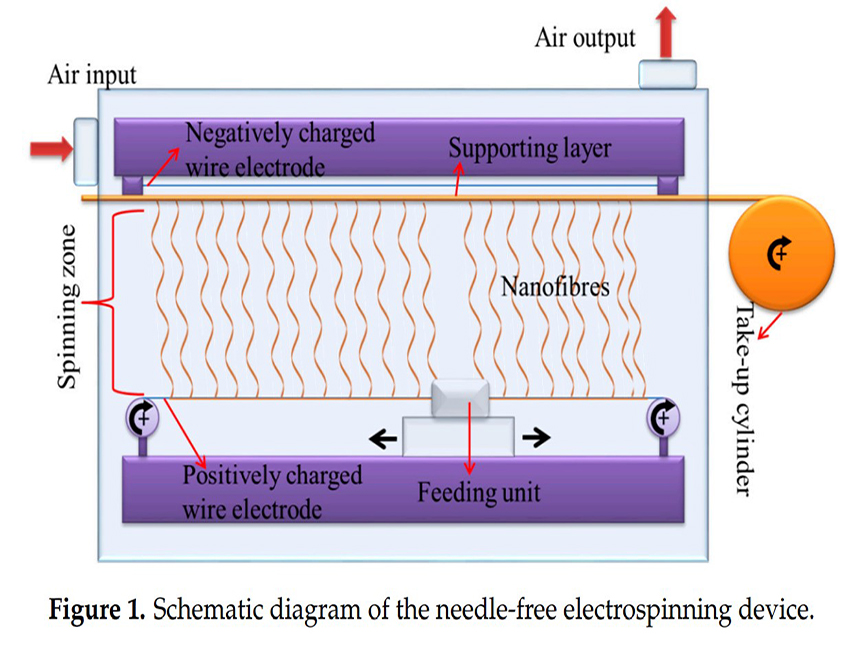

Membranes are considered as a promising technology for separation and filtration processes. Here, novel polyvinylidene fluoride (PVDF) nanofibrous multilayer membranes were fabricated by wire-based industrial electrospinning equipment following by a lamination process. The lamination process was optimised under various applied temperature, force of lamination, and lamination time. Air permeability and burst-pressure tests were run to determine the optimum membranes for filtration application. The structures of the prepared membranes were characterised by scanning electron microscopy and pore-size analysis. The hydrophilic properties of the membranes were evaluated using water contact angle measurement, and the mechanical strength of the membranes was analysed. Air and water filtration tests were run to find the possible application of prepared membranes. The air filtration results showed that membranes had high filtration efficiencies: Over 99.00% for PM2.5, and PM0.1. The water filtration results indicated that permeability of the membranes changed from 288 to 3275 L/m(2)hbar. The successful preparation of such an interesting material may provide a new approach for the design and development of electrospun filter membranes.

膜被认为是用于分离和过滤过程的有前途的技术。在这里,新型的聚偏二氟乙烯(PVDF)纳米纤维多层膜是通过基于线的工业电纺丝设备,然后进行层压工艺制成的。在各种应用温度,层压力和层压时间下对层压过程进行了优化。进行了透气性和爆破压力测试,以确定用于过滤应用的最佳膜。制备的膜的结构通过扫描电子显微镜和孔径分析来表征。使用水接触角测量评价膜的亲水性,并分析膜的机械强度。进行了空气和水过滤测试,以发现制得的膜的可能应用。空气过滤结果表明,膜具有很高的过滤效率:PM2.5和PM0.1的过滤效率均超过99.00%。水过滤结果表明,膜的渗透率从288变为3275 L / m(2)hbar。这种有趣材料的成功制备可以为电纺滤膜的设计和开发提供一种新方法。

Published: 2018

Journal :Nanomaterials and Nanotechnology

Impact Factor:2.022

Paper link: https://www.mdpi.com/2079-4991/8/10/771