© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

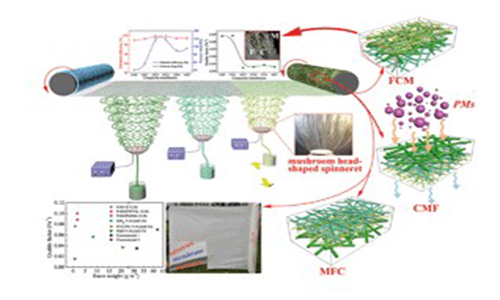

Herein, micro-gradient structured polyacrylonitrile (PAN) sub-micro fibrous membranes composed of coarse, medium, and fine (C, M, and F) fiber layers with different fiber diameters in the submicron scale range were fabricated via one-step free surface electrospinning with large-scale productivity and demonstrated for the first time as air filters, respectively. The sub-micro fibers with narrow diameter distributions of each layer were regulated precisely in the micro-gradient structure; moreover, the influence of the arrangement of the layers on the performance of the membranes was analyzed systematically, among which the F-M-C membrane displayed optimal performance (filtration efficiency of 99.28% and pressure drop of 55.86 Pa). Additionally, the filtration performance of the composite membranes could be further improved to an efficiency of 99.99% and a pressure drop of 92 Pa only by the surface modification of the finest fibrous layer. Furthermore, the micro-gradient structures of the membranes could be regulated and arbitrarily fabricated with different gradient degrees, even at the nanometer level. By polymer blending, the upgraded micro-gradient-structured filter (the average fiber diameters of each layer were only 200, 110 and 70 nm) possessed similar to 1 mu m average pore size, a large specific surface area (53.12 m(2) g(-1)) and an excellent efficiency of 99.97% (F-M-C) with a resistance of 106.8 Pa, superior to those of a homogeneous PAN filter. The results suggest that micro-gradient-structured fibrous membranes composed of C, M, and F layers with tortuous channels can efficiently separate different sized PMs from the airstream through capturing mechanisms. The cost-effective micro-gradient filter media produced by one-step free surface electrospinning is promising for industrial production and commercial applications.

在此,通过一步自由表面制造了由具有在亚微米级范围内的不同纤维直径的粗,中和细(C,M和F)纤维层组成的微梯度结构聚丙烯腈(PAN)亚微纤维膜静电纺丝技术,具有大规模生产能力,并首次作为空气过滤器首次展示。每层直径分布较窄的亚微纤维在微梯度结构中得到精确调节。此外,系统地分析了层的排列对膜性能的影响,其中F-M-C膜表现出最佳性能(过滤效率为99.28%,压降为55.86 Pa)。另外,仅通过对最细纤维层进行表面改性,就可以将复合膜的过滤性能进一步提高至99.99%的效率和92Pa的压降。此外,即使在纳米级,也可以调节和任意制造具有不同梯度度的膜的微梯度结构。通过聚合物共混,升级的微梯度结构滤光片(每层的平均纤维直径仅为200、110和70 nm)具有与1μm的平均孔径相似,较大的比表面积(53.12 m(2)) g(-1))和99.97%(FMC)的出色效率,电阻为106.8 Pa,优于均质PAN过滤器。结果表明,由具有弯曲通道的C,M和F层组成的微梯度结构纤维膜可以通过捕获机制有效地从气流中分离出不同尺寸的PM。通过一步式自由表面静电纺丝生产的具有成本效益的微梯度过滤介质有望用于工业生产和商业应用。

Published: 2019

Journal :ENVIRONMENTAL SCIENCE-NANO

Impact Factor:7.683

Paper link: https://pubs.rsc.org/--/content/articlelanding/2019/en/c9en00816k/unauth#!divAbstract