© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

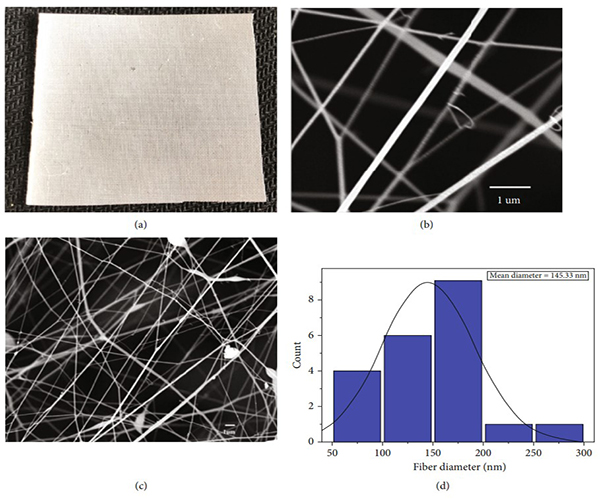

There are still some challenges for mass-scale production via electrospinning (e-spinning). For example, the cost of industrialized equipment is relatively expensive, and the subsequent maintenance costs are high. The reliability and stability of the production process are also one of the important challenges. The recycling of organic solvents and the volatilization of solvents not only affect the quality of nanofibers, but also causes environmental pollution. In this work, a new multineedle e-spinning device has been proposed for large-scale production of polymer nanofibers. The spinning solution is provided through the outside surface of the needle to avoid needle clogging problem, which is different from the traditional multineedle e-spinning. The successful preparation of thermoplastic polyurethane (TPU) nanofiber membrane with production rate similar to 50 g h(-1) proves the feasibility of the device, which also can be used to prepare other functional nanofibers such as polyvinylidene fluoride (PVDF) and polyacrylonitrile (PAN). The prepared TPU nanofiber gauze has been characterized. The average fiber diameter was 145.3 nm. The surface of the sample was found to be uniform, and the water contact angle was 138.9 degrees. The sample had gas permeability of 1500 mm s(-1), excellent PM2.5 removal efficiency of 99.897%, and optical transparency of similar to 56%, indicating that the new device has a practical application perspective.

通过静电纺丝(e-spinning)进行大规模生产仍然存在一些挑战。例如,工业化设备的成本相对昂贵,并且随后的维护成本高。生产过程的可靠性和稳定性也是重要的挑战之一。有机溶剂的循环利用和溶剂的挥发不仅影响纳米纤维的质量,而且还会造成环境污染。在这项工作中,已经提出了一种新的多针电子纺丝设备,用于大规模生产聚合物纳米纤维。通过针的外表面提供纺丝溶液,以避免针堵塞的问题,这与传统的多针电子纺丝不同。成功制备出生产率接近50 gh(-1)的热塑性聚氨酯(TPU)纳米纤维膜证明了该装置的可行性,该装置还可用于制备其他功能性纳米纤维,例如聚偏二氟乙烯(PVDF)和聚丙烯腈(PAN) )。制备的TPU纳米纤维纱布已经过表征。平均纤维直径为145.3nm。发现样品的表面是均匀的,并且水接触角为138.9度。该样品的透气度为1500 mm s(-1),极好的PM2.5去除效率为99.897%,光学透明度约为56%,表明该新设备具有实用的应用前景。

Published: 2020

Journal :Journal of Nanomaterials

Impact Factor:1.915

Paper link: https://www.hindawi.com/journals/jnm/2020/4965438/