© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

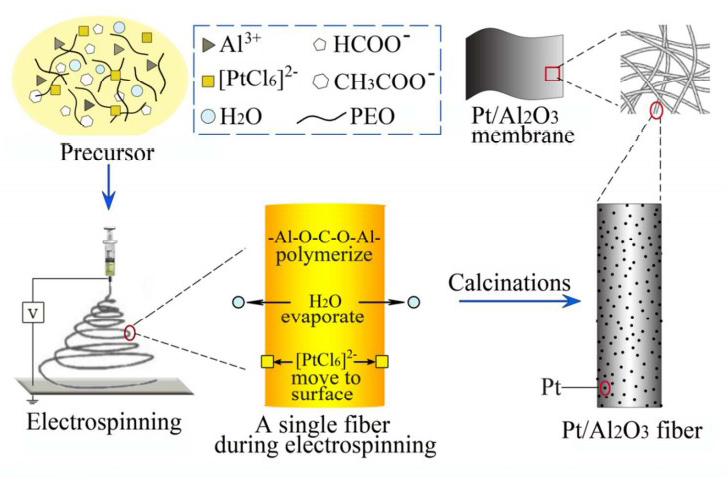

In spite of intensive research investigating the prevalent Pt/Al2O3 catalysts, achieving macroscopic morphology beyond the powder form limitations remains highly challenging. Meanwhile, current impregnation-based preparation approaches show the drawbacks of tedious procedures and inefficient use of noble metals. Therefore, it is important to search for new methods for the fabrication of Pt/Al2O3 catalysts with a novel morphology. In this study, a novel Pt/Al2O3 nanofibrous membrane catalyst is fabricated via a facile one-pot electrospinning process. The embedding of Pt nanoparticles is performed simultaneously with the formation of Al2O3 nanofibers. The Pt/Al2O3 membranes show remarkable mechanical properties with tensile stresses as high as 44.14 MPa. Notably, the Pt/Al2O3 membranes exhibit multifunctionality with excellent performance characteristics. The catalytic experiments indicate that 100% of bisphenol A is removed within 60 min, and 100% of CO is completely converted to CO2 at 242 degrees C when Pt/Al2O3 membranes are used as catalysts. The membranes also exhibit excellent filtration performance, clearly decreasing the turbidity of water, and meet the high efficiency of particulate air filter standards. The excellent flexibility, satisfying mechanical property, and multifunctionality extend the range of potential application of the Pt/Al2O3 membranes. Moreover, the facile synthesis suggests new possibilities for the fabrication of many membrane-form Al2O3-supported catalysts.

尽管进行了深入的研究以研究普遍的Pt / Al2O3催化剂,但要达到超越粉末形式限制的宏观形态仍然是极具挑战性的。同时,当前基于浸渍的制备方法显示出繁琐的程序和贵金属使用效率低下的缺点。因此,寻找具有新颖形态的Pt / Al2O3催化剂的制备新方法很重要。在这项研究中,一种新型的Pt / Al2O3纳米纤维膜催化剂是通过便捷的一锅电纺丝工艺制备的。 Pt纳米粒子的包埋与Al2O3纳米纤维的形成同时进行。 Pt / Al2O3膜表现出显着的机械性能,拉伸应力高达44.14 MPa。值得注意的是,Pt / Al2O3膜具有多功能性和出色的性能特征。催化实验表明,当使用Pt / Al2O3膜作为催化剂时,在60分钟内100%的双酚A被去除,并且在242摄氏度下100%的CO被完全转化为CO2。该膜还具有出色的过滤性能,明显降低了水的浊度,并满足了颗粒空气过滤器标准的高效率。优异的柔韧性,令人满意的机械性能和多功能性扩展了Pt / Al2O3膜的潜在应用范围。而且,容易的合成为制造许多膜形式的Al2O3负载的催化剂提供了新的可能性。

Published: 2018

Journal :ACS Applied Materials & Interfaces

Impact Factor:9.002

Paper link: https://pubs.acs.org/doi/abs/10.1021/acsami.8b07637