© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

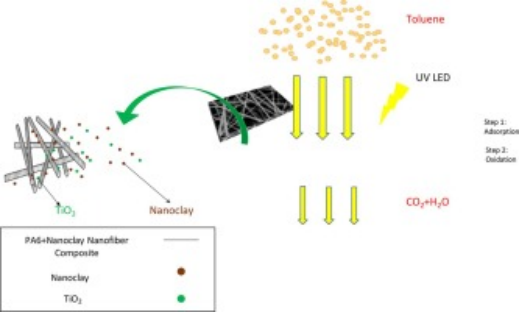

The multifunctional polyamide-6 (PA-6) electrospun nanofibers were fabricated for indoor air filtration. Nanoclay (NC) was used as nanoadsorbent, and TiO2 was preffered as nanocatalyst for photocatalytic oxidation of toluene. The main responses of study were selected as characterization (fiber diameter, tensile strength, air permeability and water vapor transmission) and performance parameters (adsorption and oxidation of toluene). These parameters of nanofibers ranged from 75.8 to 135.9 nm for fiber diameter, 0.51–3.47 MPa for tensile strength, 11.6–19.0 mm/sn for air permeability, 119.9–309.4 g/m2.h for water vapor permeability, 7.0%-43.7% adsorption efficiency at 15 min, and 7.4–12.6% oxidation efficiency at 66 min. The increase in NC content decreased the air permeability values and increased the tensile strength values of nanofibers. The adsorption efficiencies of nanofibers increased from 7% to 28.9, 35.3 and 43.7% with increasing NC ratios (0.0–0.025–0.05–0.5%). The highest CO2 production was obtained for nanofiber having 0.05% of NC and 1% of TiO2 at low UV light energy and short filtration time.

Download : Download high-res image (83KB)

Download : Download full-size image

Indoor air quality (IAQ) is an important factor in human health. Common indoor air pollutants include CO2, NOx, polycyclic aromatic hydrocarbons (PAHs), volatile organic compounds (VOCs), radon, formaldehyde, cigarette smoke, airborne allergens, pathogens, mineral fibers, polymers, and toxic emissions from consumer products [1]. VOCs are organic compounds with a boiling point of less than 250 °C and a high vapor pressure, so they evaporate readily at room temperature and atmospheric pressure [2]. When exposed to VOCs in indoor air, occupants experience a range of symptoms, including conjunctival irritation, nasal and neck pain, headaches, allergic skin reactions, and nausea, commonly referred to as sick building syndrome (SBS) [3]. Recently, many advanced technologies have been developed to remove VOCs from indoor air, such as adsorption, thermal and catalytic oxidation, filtration, bioreaction, and photocatalysis [4]. Among these, the photocatalytic oxidation is an innovative and promising approach that uses semiconductor catalysts and ultraviolet (UV) light to convert organic compounds into water (H2O) and carbon dioxide (CO2) [5]. In photocatalytic oxidation, ZnO, ZnS, CdS, Fe2O3, WO3, and TiO2 are popular photocatalytic agents, with TiO2 being the most efficient oxidant for the decomposition of a variety of VOCs [6]. In some studies, nanofibers are fabricated and successfully used by adding titanium dioxide (TiO2) to polymer composite structures [7], [8], [9]. Su et al. (2017) fabricated the nanoparticles embedded electrospun nanofibers with electrospraying of titanium dioxide (TiO2) and electrospinning of polyacrylonitrile (PAN). The results showed that the TiO2 nanoparticles exhibited high photocatalytic activity of between 33 and 97.7% for toluene [10]. In another study, ultralong TiO2 electrospun nanofibers/activated carbon fibres (TiNF/ACF) porous composites were prepared by depositing TiNFs in ACF felts and the toluene removal efficiency of composite changed in range of 65.5–87.1% under a 300 W xenon lamp [11]. In addition to photocatalytic oxidation, adsorption is an important VOC removal process that is particularly effective at low VOC concentrations [12]. Adsorption with activated carbon (AC) is widely used for the removal of VOCs [13]. Other alternative adsorption materials include activated carbon fibres, zeolites, porous clay ore, nanoclay, activated alumina, silica gel, and/or molecular sieves [14]. Nowadays, nanoclay (layered silicates) has become one of the ideal nanoadsorbents due to its high aspect ratio, ease of use, low cost, good dispersion properties and non-toxicity [15], [16]. Nanoclay is a general term for naturally occurring, layered mineral clay silicate nanoparticles with a layer thickness of about 1 nm, with phyllosilicate or sheet structure [17]. Regarding the application of nanoclay in air filters, a polyurethane/clay nanocomposite filter with modified clay content was prepared in the literature by Herrera-Alonso et al [18]. They studied the adsorption–desorption cycles of VOCs in indoor air and found that the use of nanoclay formed a more structured surface for adsorption on VOC molecules. Thermodynamic analysis showed that the wetting properties of material played a more effective role in VOC adsorption.

Choosing the right filter material is one of the most important issues for successful and sustainable VOC removal of pollutants, especially in indoor air filtration devices. Recently, the electrospun nanofibers have been promoted as innovative materials for indoor air filters and offer unique advantages due to their specific properties such as high porosity, small fiber diameters, pore crosslinking ability, large specific surface area, flexibility in surface functionality, and excellent pore size adjustability. Electrospinning is considered as the most promising technology for the fabrication of electrospun nanofiber filters [19]. Polar polymer electrospun nanofibrous membranes (ENMs) have higher filtration efficiency and lower pressure drop. Polyamide-6 (PA-6), the most widely used polymer, is a promising candidate as an air filter material [20]. PA-6 is a biodegredable and biocompatable semi crystalline polymer and is one of the most commonly used engineering materials due to its superior mechanical properties such as high tensile and impact strength, and has excellent chemical stability and thermal resistance [21], [22], [23]. Polyamides dissolve in non-volatile as well as non-toxic solvents; they are usually dissolved in formic acid or formic acid/acetic acid mixture and this results in easiness for fiber formation via electrospinning and also provides environmentally-friendly process in comparision with other toxic solvents [21]. Diameters of electrospun PA-6 nanofibers vary in a large range scale (e.g. a few nanometers to hundreds of nanometers) depending on electrospinning conditions and are used as membrane materials for both water and air filtration application s with high filtration efficiencies [24], [25], [26]. In addition to superior thermal and mechanical properties of PA-6 nanofibers, low dielectric constant and high breakdown voltage suggest good ability of PA-6 nanofibers to retain electrical charges and this is one other adventageous in filtration applications due to electrostatic attraction [27].

An increase of NC concentration in polymer solution decreases the agglomeration and this leads to a decrease in tensile strength values [28]. Marsano et al [29] reported that increasing the concentration of PA-6 polymer solution improved the mechanical strength of the fibers and showed good mechanical properties. In a study, it was found that the addition of TiO2 to the polyetherimide (PEI) electrospun nanofiber structure improved the tensile strength of the electrospun nanofiber [30]. However, a decrease in tensile strength values was observed at higher TiO2 concentrations. The superior filtration performance and low air resistance make nylon electrospun nanofibers a promising candidate for air filtration [31]. These features contribute to the advantageous properties of electrospun nanofiber filters, such as low pressure drop, high permeability, and low operating cost [32], [33]. At the same time, the electrospun nanofiber filters have high adsorption efficiency and high recoverability, which also make them effective adsorbents [34].

The aim of this study is to fabricate PA-6 electrospun nanofiber air filters with homogeneous nanoadditive dispersions, uniform fiber size distribution, moderate adsorption and oxidation efficiencies, and good mechanical strength, and to monitor their removal performance in a simulated setup for real indoor air conditions. The electrospun polyamide-6 (PA-6) composite nanofiber air filters were fabricated with multifunctional properties such as high adsorption and oxidation efficiencies, improved mechanical strength and good air permeability. The novelties of our study are (i) fabrication of multifunctional (adsorptive, oxidative and air permeable) PA6 nanoclay composite electrospun nanofiber indoor air filters, which are long-term, self-cleaning and low-cost mateirals, (ii) oxidation of toluene with low intensity UV light and short reaction time, (iii) clarification of adsorption and oxidation mechanism in indoor air filters. Nanofiber air filters will be an important component for indoor air purification devices to improve indoor air quality/hygiene in the next few years due to their low energy consumption, long-term use, self-cleaning, low cost, and multifunctionality.

Nanoclay (NC) (Purity: 99.9%, Size: 400–500 nm, NG10SM0101) and PA-6 (ULTRAMID B24, MW ∼ 145,000 g.mole-1) were purchased from Nanografi and BASF, respectively. TiO2 (anatase form) was purchased from Sigma-Aldrich. The particle size of TiO2 is about 100–200 nm. Acetic acid (100% purity, 100056.2500) and formic acid (98–100% purity, 1.00263.2500) were used as solvents to prepare the polymer solution and were purchased from Merck. Support layer has the following properties: white, 100%

The chemical structure of the fabricated electrospun nanofibers was investigated by FTIR analysis and is shown in Fig. 3-a and b as four main groups. The 2932 and 2857.1 cm−1 peaks in the FTIR spectrum of PA −6 polymer show the CH bond, the 1462.7 cm−1 peak shows the CH2 bond, and the 1643, 1545.2 and 1235.5 cm−1 peaks show the amide groups in the polyamide [39]. Pang et al [7] found that the range of 500–800 cm−1 is due to the Ti-O bond. New peaks appear at 1170.5, 1017 and 667 cm−1 in

Electrospun polyamide-6 (PA-6) composite nanofibers including NC and TiO2 were fabricated with electrospinning for indoor air filtration. The fabricated multifunctional indoor air filters can adsorb and oxidize toluene at low UV light energy and in a short filtration time. These filters will be an important component for indoor air filtration devices to improve indoor air quality in the next few years because they have low energy requirements, long-term use, self-cleaning, low cost, and

Dila Aydin: Experimental Design, Review of Experimental Data, Analysis of Experimental Data, Characterization Tests, writing of the manuscripts, modification of the manuscripts. Elifnur Gezmis-Yavuz: Experimental Design, Review of Experimental Data, Analysis of Experimental Data, Characterization Tests, writing of the manuscripts, modification of the manuscripts. Esra Buyukada-Kesici: Experimental Design, Characterization Tests, writing of the manuscripts. Derya Yuksel Koseoglu-Imer: Project...