© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

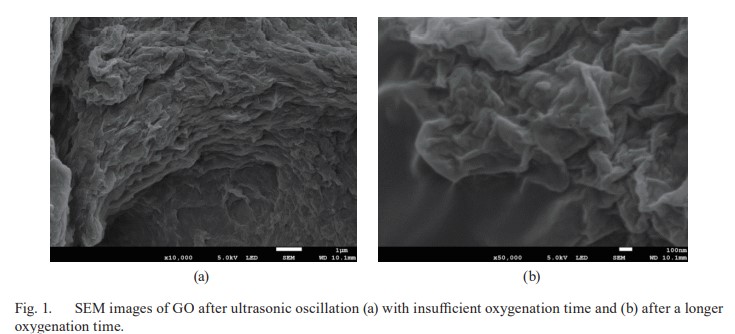

In this study, an electrospinning solution was first varied, then the ratio of different solvents was varied. The effects of the viscosity and conductivity of the clectrospinning solution on the fiber were further investigated to find optimal parameters. It was found that a high viscosity not only increased the fiber diameter, but also sometimes caused agglomeration. A material tester was used to evaluate the mechanical strength of the fiber membrane for different solvent ratios. The optimal solvent ratio was obtained by comparing the effects of different weight ratios of graphene oxide (GO) on the fiber membrane. GO increased the conductivity, and fine fibers were obtained when 0.8 wt% GO was added. After adjusting the main parameters of electrospinning, the best fiber film was prepared. By adding a suitable amount of GO, the mechanical strength and thermal cracking properties of the fiber membrane were improved, and the filtration rate of PM2.5 was as high as 98%.

在这项研究中,首先改变静电纺丝溶液,然后改变不同溶剂的比例。 进一步研究了电纺丝溶液的粘度和电导率对纤维的影响,以找到最佳参数。 发现高粘度不仅增加了纤维直径,而且有时引起团聚。 使用材料测试仪来评估不同溶剂比率下纤维膜的机械强度。 通过比较不同重量比的氧化石墨烯(GO)对纤维膜的影响,可以获得最佳的溶剂比。 GO增加了电导率,并且当添加0.8重量%的GO时获得了细纤维。 调整静电纺丝的主要参数后,可以制备出最佳的纤维膜。 通过添加适量的GO,纤维膜的机械强度和热裂性能得到改善,PM2.5的过滤率高达98%。

Published: 2020

Journal :SENSORS AND MATERIALS

Impact Factor:0.685

Paper link: https://www.myukk.org/SM2017/sm_pdf/SM2147.pdf