© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

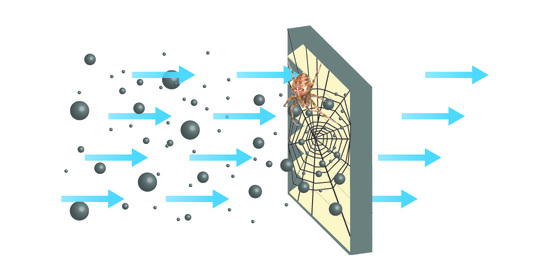

Filtration systems used in technical and medical applications require components for fine particle deep filtration to be highly efficient and at the same time air permeable. In high efficiency filters, nonwoven meshes, which show increased performance based on small fiber diameters (e.g., using nanofibers), can be used as fine particle filter layers. Nanofiber nonwoven meshes made by electrospinning of spider silk proteins have been recently shown to exhibit required filter properties. Needle-based electrospinning, however, is limited regarding its productivity and scalability. Centrifugal electrospinning, in contrast, has been shown to allow manufacturing of ultrathin polymer nonwoven meshes in an efficient and scalable manner. Here, continuous roll-to-roll production of nonwoven meshes made of recombinant spider silk proteins is established using centrifugal electrospinning. The produced spider silk nanofiber meshes show high filter efficiency in the case of fine particulate matter below 2.5 mu m (PM2.5) and a low pressure drop, resulting in excellent filter quality.

技术和医疗应用中使用的过滤系统要求用于微粒深层过滤的组件必须高效且同时具有透气性。在高效过滤器中,基于小纤维直径(例如,使用纳米纤维)显示出提高的性能的非织造筛网可以用作细颗粒过滤器层。最近已经显示出通过静电纺制蜘蛛丝蛋白制成的纳米纤维非织造网具有所需的过滤性能。但是,基于针的静电纺丝在生产率和可扩展性方面受到限制。相比之下,离心静电纺丝已显示出可以以有效且可扩展的方式制造超薄聚合物非织造网片。在这里,使用离心静电纺丝技术可以连续卷对卷地生产由重组蜘蛛丝蛋白制成的非织造网。所制得的蜘蛛丝纳米纤维网在细颗粒物低于2.5微米(PM2.5)的情况下显示出高过滤效率,并且压降低,因此具有出色的过滤效果。

Published: 2020

Journal : BIOMACROMOLECULES

Impact Factor:6.323

Paper link: https://www.mdpi.com/1420-3049/25/23/5540