© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

1. The development history of filtration technology: innovation from traditional filter paper to nanofiber filter paper

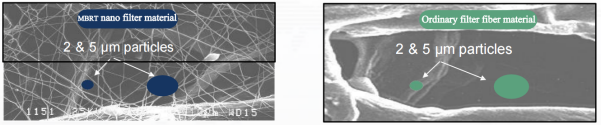

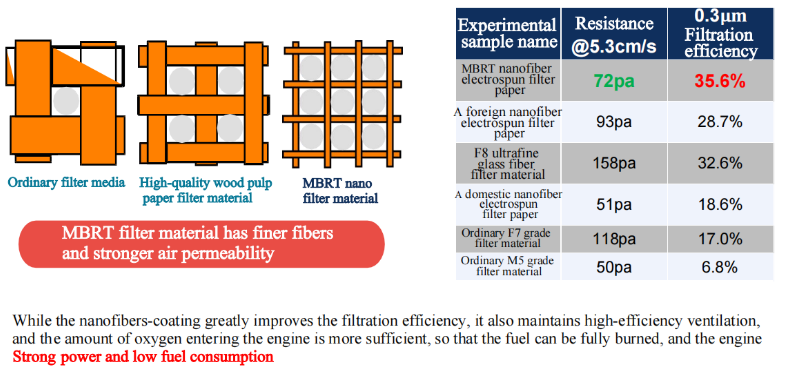

Nanofiber filter material is coated with nanofiber items on the surface of ordinary wood pulp filter paper through high-voltage electrospinning, and the filter material with different filtration precision F7~E10 (EN779-2012) is made by adjusting the spray distribution.

Nanofiber-spray coating technology can significantly reduce the pore size of the filter paper, greatly increase the specific surface area, intercept more fine particles on the surface of the filter paper, and change the filtration mechanism from deep filtration to surface filtration.

The high bonding strength of nanofibers to the substrate makes nanocomposites ideal for pulse cleaning applications.

2. Nanofiber Filter Paper and Why It Matters

Nanofiber filter paper greatly improves the filtration efficiency and dust holding capacity of the original original substrate, and the level of composite nanofiber reaches the international advanced level. Whether it is a steam engine, a gas turbine, or a diesel engine, a more high-quality air system is required to exert the best performance of the power system. , By providing high-quality air, the equipment can provide reliable protection for the power part especially in harsh environments, thereby prolonging the service life and reducing the use and maintenance costs. Provide blade protection for generators and compressors in the equipment, so that the hydraulic device and lubrication system can always be kept in good condition.

Click to Lern more detail about Nanofiber Filter Paper: Nanofiber Cartridges For Air Filtration

A vehicle uses our MBR8W402 F8 grade nanofiber filter paper to make a filter.

Case 1.The air intake flow rate of a vehicle under normal working conditions is 700m³/h, and the dust concentration in the working environment is 40mg/m³. The comparison of the ash intake amount of the engine in a year using the Membrane Tech air filter and the ordinary air filter respectively:

|

Annual air consumption: |

700m³/hour×8 hours/day×365 days=2044000m³ |

|

Use Mybreath Air Filter |

Amount of dust entering the engine: 2044000m³×0.00004Kg/m³*0.03%=0.0245Kg ( 24.5g ) |

|

Use ordinary air filter |

Amount of dust entering the engine: 2044000m³×0.00004Kg/m³*0.5%=0.4088Kg ( 408.8g ) |

|

High-precision filtration is more effective in protecting the engine, and less dust enters the engine |

|

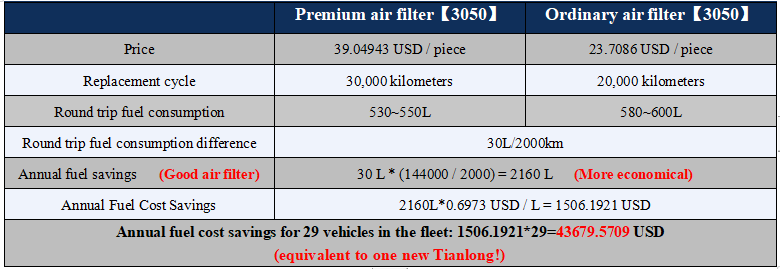

Case 2.

Client: Wuhan Boss Li Racing Team

Transportation route: Wuhan-Guangzhou special line

Transportation distance: about 2000 kilometers round trip

Vehicles: 29 Dongfeng Tianlong KL420

Shipping target: auto parts

Mileage: 6 trips/month, 14.4w km/year

1. Large ash capacity

Compared with traditional filter materials, nanofibers are finer and more uniform, with large ash holding capacity, and the service life is more than 3 times that of ordinary filter elements.

2. Dust can fall off automatically

The extremely fine nanofibers make the pollutants form a filter cake on the surface of the filter paper, which will fall off automatically with the vibration during the operation of the vehicle.

3. High-strength nanofibers-layer, super strong adhesion and tear resistance

The use of PVDF nanofibers-materials has high strength, corrosion resistance, and super adhesion to ensure that the nanofibers-layer is not easily damaged. most competitors The problem of adhesion of the nanofibers layers is not addressed.

4. Waterproof and antifouling

The nanofibers-layer of Maiborui has unique water-repelling properties, strong anti-fouling ability, dust is not easy to adhere, and the service life is extended

Nanofiber filter paper has the characteristics of long life and strong performance, and has been recognized by more and more users and is worth purchasing.

We have many nanofiber filter paper for you to choose. If you have any question about nanofiber filter pape, please contact us.

WahtsApp: +86 13450760218

Message Box: Page Link