© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

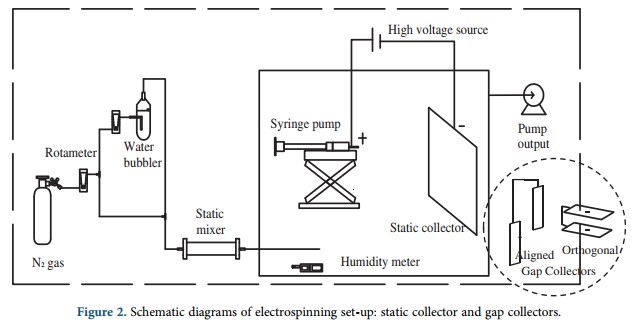

Nanofibers for fine dust filters of four structures (random, aligned, orthogonal, and nanofiber net) were prepared by electrospinning method using polymers such as PAN and PA6. While conventional electret filters experienced deterioration problems in fine dust(PM1.0) capture as its surface charge decayed, the electrospun nanofibers prepared contributed to the removal capacity. The filters from aligned fibers showed high quality factors (q(F): filter performance indicator) and filtration efficiency from 22 to 50% depending on particle size than simple electret media at a face velocity of 15.92 cm/s. The fiber structure of nanofiber net (NFN) presented almost absolute collection efficiency, particularly on dust particles smaller than 300 nm. Furthermore, the composite filters which are composed both of a commercial electret mask filters and nanofiber nets effectively enhanced the overall filtration efficiency by 59.46%, resulting in more than 99% for PM1.0. Consequently, electrospun polymer nanofibers offer a promising plausible mask filter material with air permeability. (c) 2019 Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2019, 136, 48166.

通过静电纺丝法,使用PAN和PA6等聚合物,制备了具有四种结构(无规,排列,正交和纳米纤维网)的细尘过滤器用纳米纤维。尽管传统的驻极体过滤器会随着表面电荷的衰减而在捕获细粉尘(PM1.0)时遇到劣化问题,但制备的电纺纳米纤维却对去除能力有所贡献。由排列好的纤维制成的过滤器在表面速度为15.92 cm / s的情况下,比简单的驻极体介质的过滤器显示出较高的品质因数(q(F):过滤器性能指标),过滤效率取决于颗粒大小,为22%至50%。纳米纤维网(NFN)的纤维结构几乎具有绝对的收集效率,尤其是在小于300 nm的灰尘颗粒上。此外,由商用驻极体掩模过滤器和纳米纤维网组成的复合过滤器有效地将整体过滤效率提高了59.46%,从而使PM1.0的回收率超过了99%。因此,电纺聚合物纳米纤维提供了一种有希望的,具有透气性的合理的面膜过滤材料。 (c)2019年Wiley Periodicals,Inc.J.Appl。 Polym。科学2019,136,48166。

Published: 2019

Journal :JOURNAL OF APPLIED POLYMER SCIENCE

Impact Factor:2.668

Paper link: https://onlinelibrary.wiley.com/doi/abs/10.1002/app.48166