© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

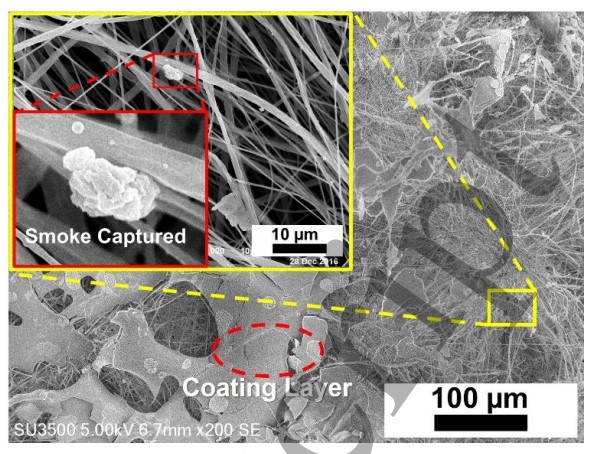

This paper reports on the recycling of expanded polystyrene (EPS) waste to be repurposed as EPS nanofibrous mats for air filtration applications. The EPS nanofibrous mats were prepared via electrospinning technique. The EPS solutions for producing the mats were made by dissolving the EPS waste in dimethylformamide (DMF) and d-limonene solvents. The mixing ratio of DMF and d-limonene solvents were varied to obtain EPS solutions with different surface tension and viscosity. As a result, different fiber morphology (smooth fiber, wrinkled fiber, and beaded fiber) and diameter ranging from 314 nm to 3506 nm were obtained. The synthesized EPS nanofibrous mats were characterized by scanning electron microscope, Fourier-transform infrared spectroscopy, x-ray diffraction spectroscopy, differential scanning calorimetry, mechanical strength, porosity, and water contact angle measurement apparatus. The mechanical strength measurement exhibited that the beaded fiber had the highest tensile strength and the lowest elasticity compared to wrinkled and smooth fiber. The water contact angle measurement showed that the EPS nanofibrous mats were classified as ultra-hydrophobic, which was a good criterion for air filter media. Some filtration parameters of the EPS nanofibrous mats were measured, including particle collecting efficiency, pressured drop, and quality factor. The particle collecting efficiency of each EPS nanofibrous mats was measured using monodisperse polystyrene latex (PSL) particles and PM2.5 from burning incense as the test particles. The EPS nanofibrous mats had a high collecting efficiency (up to 99.99%) and had a low pressure drop (below 70 Pa) for the face velocity of 5.4 cm s(-1). The quality factor of the EPS nanofibrous mats reached 0.10 for PSL filtration and 0.16 for PM2.5 filtration. Overall, the EPS nanofibrous mats with controlled morphology were suitable to be used as air filtration media with high mechanical strength, ultra-hydrophobic.

本文报道了膨胀聚苯乙烯(EPS)废物的回收利用,这些废物将被重新用作空气过滤应用的EPS纳米纤维垫。通过静电纺丝技术制备了EPS纳米纤维毡。通过将EPS废料溶解在二甲基甲酰胺(DMF)和d-柠檬烯溶剂中制得用于生产垫子的EPS解决方案。改变DMF和d-柠檬烯溶剂的混合比例以获得具有不同表面张力和粘度的EPS溶液。结果,获得了在314nm至3506nm范围内的不同纤维形态(光滑纤维,皱纹纤维和串珠纤维)和直径。通过扫描电子显微镜,傅立叶变换红外光谱,X射线衍射光谱,差示扫描量热法,机械强度,孔隙率和水接触角测量装置对合成的EPS纳米纤维垫进行了表征。机械强度的测量表明,与起皱和光滑的纤维相比,该串珠纤维具有最高的拉伸强度和最低的弹性。水接触角测量表明,EPS纳米纤维毡被归类为超疏水性,这是空气过滤介质的良好标准。测量了EPS纳米纤维毡的一些过滤参数,包括颗粒收集效率,压降和品质因数。使用单分散聚苯乙烯胶乳(PSL)颗粒和燃烧香气中的PM2.5作为测试颗粒,测量了每个EPS纳米纤维垫的颗粒收集效率。 EPS纳米纤维毡具有很高的收集效率(高达99.99%),并且在5.4 cm s(-1)的面速度下具有较低的压降(低于70 Pa)。对于PSL过滤,EPS纳米纤维毡的品质因数达到0.10,对于PM2.5过滤,其质量因数达到0.16。总体而言,具有可控形态的EPS纳米纤维毡适合用作具有高机械强度,超疏水性的空气过滤介质。

Published: 2019

Journal :NANOTECHNOLOGY

Impact Factor:3.54

Paper link: https://iopscience.iop.org/article/10.1088/1361-6528/ab2e3b/meta