© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

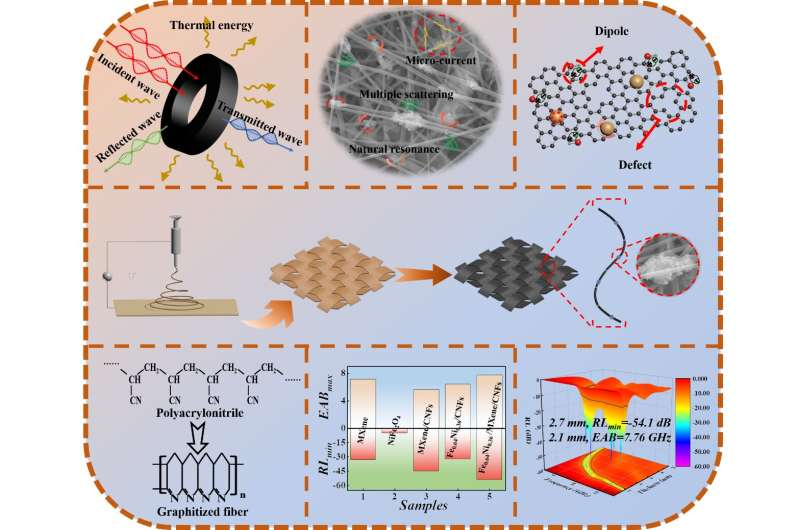

(A cartoon showing MXene and magnetic nanoparticles embedded in nanosheets and formed into fabric threads out of the electrospinning syringe. Credit: Nano Research, Tsinghua University Press)

Engineers have employed "electrospinning," a new technique of manufacturing nanomaterials, to produce a novel fabric that offers high performance protection against electromagnetic interference, a phenomenon that can result in electronic device malfunction and at high levels of exposure can harm human health.

The technique is described in a paper published in Nano Research on December 31, 2022.

Electric and magnetic fields generated by electrical equipment can negatively interfere with digital systems either internally or externally. Such disruption can result in dangerous malfunctions if such devices are operating close to each other, particularly in the case of transportation or medical equipment such as pacemakers and insulin pumps. This interference can not only affect electronic devices, but at very high levels over short periods, it can also put at risk human biology, which in part makes use of bioelectromagnetic processes.

For all these reasons, a great deal of effort goes into shielding people, devices and parts of devices from electromagnetic interference. To avoid making devices—particularly wearable ones—overly bulky and heavy, such shielding also needs to be lightweight and flexible.

Since the 1960s, such shielding has focused on the use of metal wire fabrics, metal wire blended with chemical fibers, and silver plating. The high cost and poor flexibility, however, were major barriers to widespread acceptance of such electromagnetic protective fabrics.

More recently, and largely thanks to the electromagnetic shielding needs of military stealth technologies, novel carbon-based materials from graphene to carbon aerogels and carbon nanotubes have been applied with great success in various electromagnetic absorption and shielding applications. Thanks to the special structures of these materials, at the microscopic scale and the nanoscale, that mainly rely on scattering and reflection of radiation between layers, as well as electron transfer, to achieve high attenuation of electromagnetic waves. They also benefit from their high electrical conductivity and surface area, light weight, flexibility, and environmental sustainability.

The technique is described in a paper published in Nano Research on December 31, 2022.

Electric and magnetic fields generated by electrical equipment can negatively interfere with digital systems either internally or externally. Such disruption can result in dangerous malfunctions if such devices are operating close to each other, particularly in the case of transportation or medical equipment such as pacemakers and insulin pumps. This interference can not only affect electronic devices, but at very high levels over short periods, it can also put at risk human biology, which in part makes use of bioelectromagnetic processes.

For all these reasons, a great deal of effort goes into shielding people, devices and parts of devices from electromagnetic interference. To avoid making devices—particularly wearable ones—overly bulky and heavy, such shielding also needs to be lightweight and flexible.

Since the 1960s, such shielding has focused on the use of metal wire fabrics, metal wire blended with chemical fibers, and silver plating. The high cost and poor flexibility, however, were major barriers to widespread acceptance of such electromagnetic protective fabrics.

More recently, and largely thanks to the electromagnetic shielding needs of military stealth technologies, novel carbon-based materials from graphene to carbon aerogels and carbon nanotubes have been applied with great success in various electromagnetic absorption and shielding applications. Thanks to the special structures of these materials, at the microscopic scale and the nanoscale, that mainly rely on scattering and reflection of radiation between layers, as well as electron transfer, to achieve high attenuation of electromagnetic waves. They also benefit from their high electrical conductivity and surface area, light weight, flexibility, and environmental sustainability.