© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

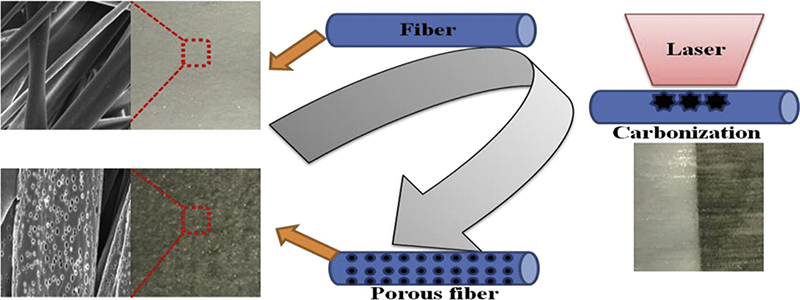

With the development of industry, the harm caused by volatile organic compound (VOC) gases to the human body has received much attention. This study reveals as the first attempt to apply laser irradiation technique to the preparation of porous electrospun fibers with excellent low-concentration VOC gases adsorption properties. The laser-sensitive polycarbonate (PC) fibers prepared from electrospinning was treated in air by scanning with a neodymium-doped yttrium aluminum garnet (Nd: YAG) pulsed laser beam to achieve porous structure. During the laser irradiation process, a series of changes such as melting, thermal degradation, and carbonization of the polymer fibers can change the surface structure. The morphology of the porous structure is related to the degree of laser-induced carbonization, and the laser current is an important parameter for determining the degree of laser-induced carbonization of a particular polymer. The results indicate that porous carbon structures can be created on the surface of the fiber membrane by controlling the degree of laser-induced carbonization, and a highly xylene gas adsorption efficiency is exhibited. This study may provide useful insights for developing electrospun porous fibers with VOC adsorption by simple, effective and environmentally friendly laser postprocessing process.

随着工业的发展,挥发性有机化合物(VOC)气体对人体的危害已引起广泛关注。这项研究揭示了将激光辐照技术应用于制备具有优异的低浓度VOC气体吸附性能的多孔电纺纤维的首次尝试。在空气中,通过掺钕钇铝石榴石(Nd:YAG)脉冲激光束扫描,在空气中处理了由静电纺丝制成的激光敏感聚碳酸酯(PC)纤维,从而获得了多孔结构。在激光辐照过程中,聚合物纤维的熔融,热降解和碳化等一系列变化可以改变表面结构。多孔结构的形态与激光诱导的碳化程度有关,并且激光电流是确定特定聚合物的激光诱导的碳化程度的重要参数。结果表明,通过控制激光诱导的碳化程度,可以在纤维膜的表面上形成多孔碳结构,并且表现出高的二甲苯气体吸附效率。这项研究可为通过简单,有效和环保的激光后处理工艺开发具有VOC吸附能力的电纺多孔纤维提供有用的意见。

Published: 2020

Journal :JOURNAL OF HAZARDOUS MATERIALS

Impact Factor:9.52

Paper link: https://www.sciencedirect.com/science/article/abs/pii/S0304389420309651