© Copyright 2020 Foshan Membrane Technology Co., Ltd. All rights reserved. Sitemap

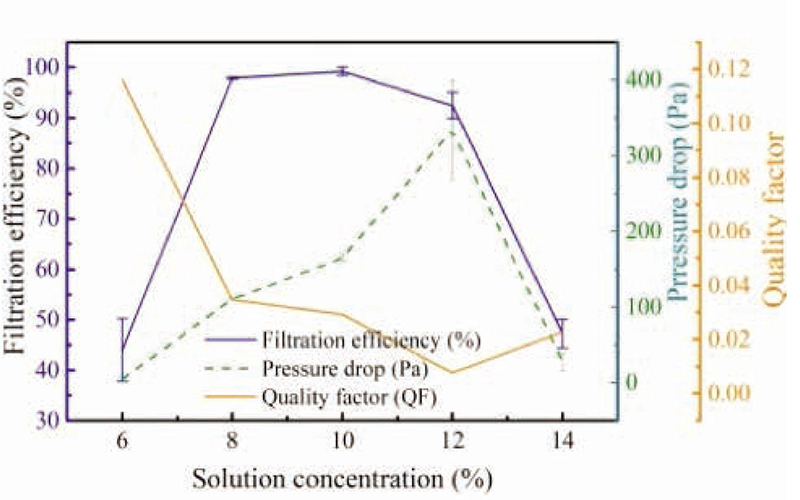

Polyvinylidene fluoride (PVDF) fibrous membranes with fiber diameter from nanoscale to microscale were prepared by electrospinning. The structural parameters of PVDF fibrous membrane in terms of fiber diameter, pore size and its distribution, porosity or packing density, thickness, and areal weight were tested. The relationship between solution concentration and structural parameters of fibrous membrane was analyzed. The filtration performance of PVDF fibrous membrane in terms of air permeability and filtration efficiency was evaluated. The results demonstrated that the higher solution concentration led to a larger fiber diameter and higher areal weight of fibrous membrane. However, no regular change was found in thickness, porosity, or pore size of fibrous membrane under different solution concentrations. The air permeability and filtration efficiency of fibrous membrane had positive correlations with pore size. The experimental results of filtration efficiency were compared with the predicted values from current theoretical models based on single fiber filtration efficiency. However, the predicted values did not have a good agreement with experimental results since the fiber diameter was in nanoscale and the ratio of particle size to fiber diameter was much larger than the value that the theoretical model requires.

通过电纺丝制备了具有从纳米级到微米级的纤维直径的聚偏二氟乙烯(PVDF)纤维膜。测试了PVDF纤维膜的结构参数,包括纤维直径,孔径及其分布,孔隙率或堆积密度,厚度和单位面积重量。分析了溶液浓度与纤维膜结构参数之间的关系。评价了PVDF纤维膜的透气性和过滤效率的过滤性能。结果表明,较高的溶液浓度导致较大的纤维直径和较高的纤维膜单位面积重量。然而,在不同溶液浓度下,纤维膜的厚度,孔隙率或孔径没有规律的变化。纤维膜的透气度和过滤效率与孔径呈正相关。将过滤效率的实验结果与基于单纤维过滤效率的当前理论模型的预测值进行比较。但是,由于纤维直径为纳米级,且粒径与纤维直径之比远大于理论模型所需的值,因此预测值与实验结果不一致。

Published: 2020

Journal :Autex Research Journal

Impact Factor:1.407

Paper link: https://sciendo.com/article/10.2478/aut-2019-0043